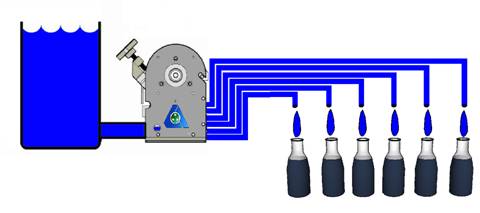

DosingAccuStaltic peristaltic pumps are ideal for dosing and filling when the application requires the special capabilities of a peristaltic pump. They can be operated at a very low flow rate for long periods of time or cycled for a periodic dose or filling application. The multi-channel industrial quality design makes them perfect for production lines and precise chemical metering to multiple locations. |

|

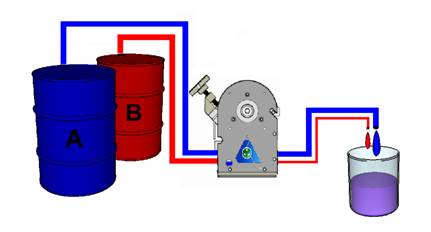

Accurately Metered Dosing:AccuStaltic multi-channel peristaltic pumps are ideal for injecting precise amounts of chemical into an operating process. Applications ranging from extracting precious metals from ore to critical treatment of waste water. Our peristaltic proportioning pumps are industrial grade equipment designed to be used where harsh chemicals must be pumped with extreme reliability. The tubing materials available allow them to pump virtually any chemical, from acids to caustics. Even viscous liquids and suspended solids can be metered and pumped with precise accuracy. |

|

AccuStaltic peristaltic pumps are available with a variable speed motor and controller which can automatically change pump output in response to a control signal. With proper instrumentation, a pH sensor for example, and a standard PLC controller, the motor speed can be changed to increase or decrease the amount of chemical being injected into the process. Since peristaltic pumps do not require priming, and ensure no flow when stopped, they can inject the proper dose at any rate and be stopped for any period of time before the next dose. AccuStaltic pumps with a VFD drive system are ideal to control chemical proportioning automatically. |

|